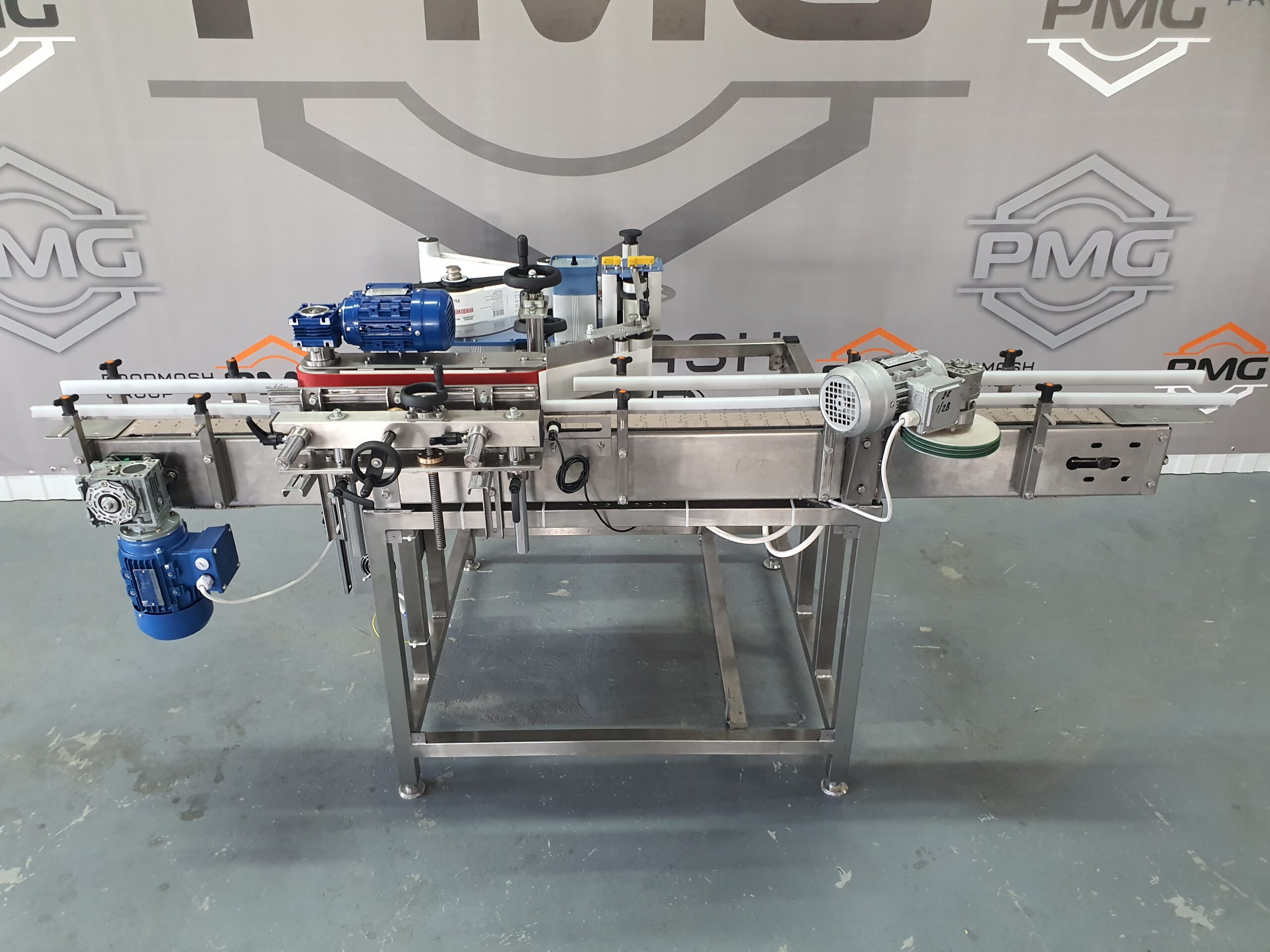

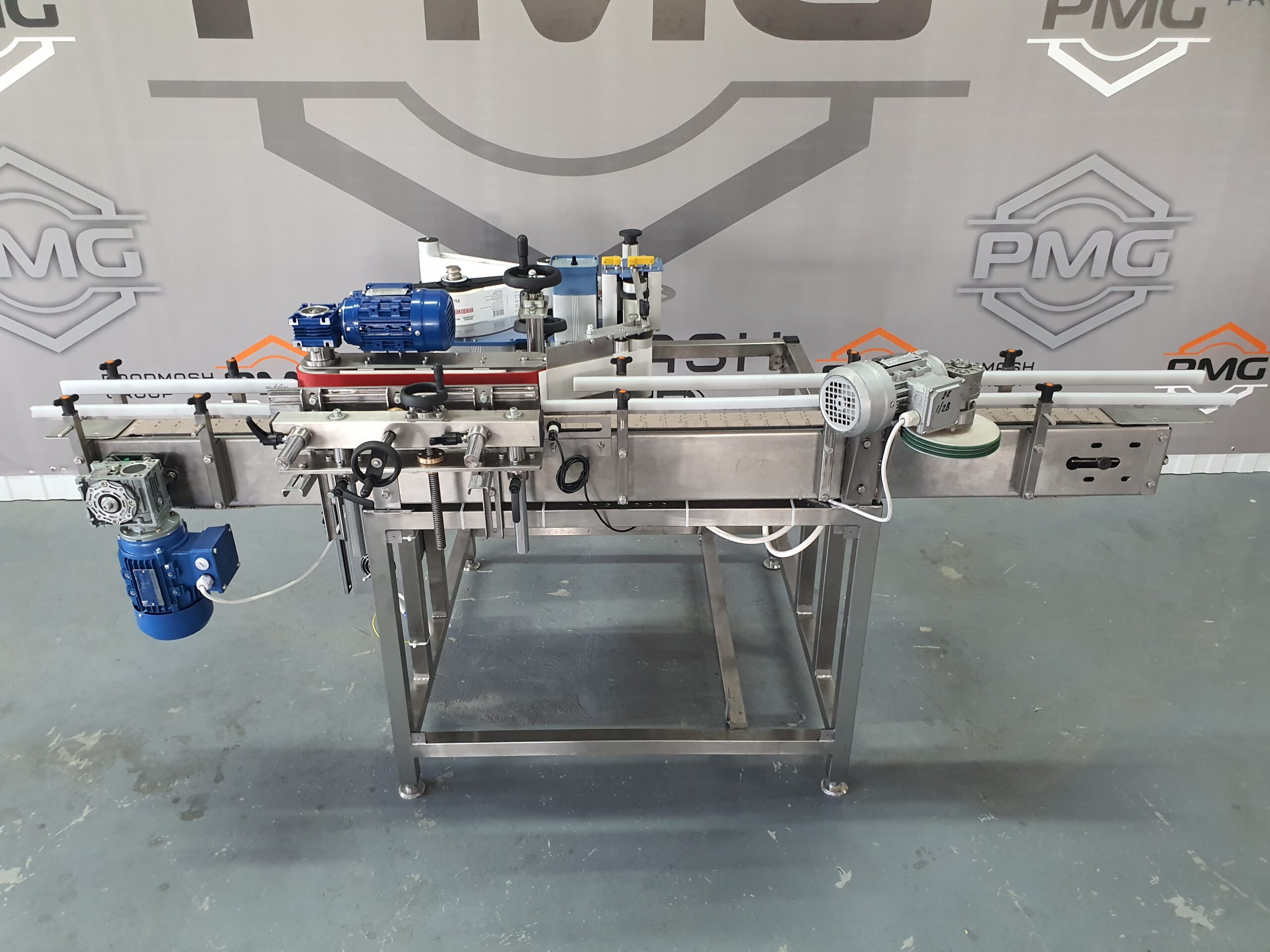

Labeling machine SK-3P for applying self-adhesive labels

Labeling equipment is designed for precise application of self-adhesive labels on both sides of flat, oval, and rectangular containers. Ensures stable speed, uniform labeling, and high label positioning accuracy. An ideal solution for canning, food, and chemical enterprises seeking to automate one-sided or double-sided labeling processes

The labeling machine is used for automatic application of self-adhesive labels on both sides of various flat, oval, and rectangular containers — bottles, flasks, jars, and plastic containers. The equipment provides even, precise, and aesthetic label application without wrinkles or misalignment, supports continuous production cycles, and replaces manual labor.

The construction is made of food-grade stainless steel AISI 304, ensuring durability, moisture resistance, and easy cleaning. The labeling machine is compatible with conveyor lines and can operate as a standalone unit or as part of a complete labeling production line.

Advantages:

-

Precise double-sided self-adhesive label application;

-

Handles flat, oval, and rectangular containers;

-

Stable speed and high productivity;

-

Uniform labeling without wrinkles or misalignment;

-

Reliable mechanical construction;

-

Easy maintenance and adjustment.

Design Features:

-

Two independent applicators for labeling both sides;

-

Self-adhesive label feed mechanism with speed adjustment;

-

Roll tension system for smooth label feed;

-

Quick roll replacement mechanism;

-

Safety guards for operator protection;

-

Easy adjustment for different container sizes and shapes.

Application Areas:

-

Canning industry — vegetables, meat, fish preserves, baby food;

-

Food industry — beverages, sauces, jams, pâtés;

-

Cosmetics and household chemicals — labeling bottles, jars, and packages;

-

Light industry — applying labels on various products and containers.

Technical specifications

| Productivity | up to 6000 labels/hour |

| Label feed speed | up to 16 m/min |

| Labeling accuracy | up to ±1.0 mm |

| Label length | up to 350 mm |

| Label height | up to 170 mm (more on request) |

| Label roll diameter | up to 310

Technical specifications mm |

| Diameter of the bobbin mounting hole | 37–80 mm |

| Power source | 230 V/50 Hz/1 ph |

| Total power consumption (total in max configuration), kW | 1.1 |

| Main conveyor length | 2 m |

| Main conveyor width | 82.5 mm / 114.5 / 153.2 mm |

| Number of applicators | up to 3 (with the possibility of vertical installation) |

| Additional equipment | |

| Orientator | 2-sided tape |

| Divider | 2-sided belt / screw / 1-sided roller |

| Upper conveyor | height adjustable |

| Applicator stand | 4-position |

| Container | |

| Types of packaging: | SKO, PET, Tin, Paper |

| Container format: | Round, Oval, Rectangular, Conical |

Інші наші товари

MANUAL sealing machine 2

MANUAL sealing machine 1

Semi-automatic sealing machine

AUTOMATIC sealing machine

AUTOMATIC Lux sealing machine

Slat Chain Conveyor for Containers

P1-BWM Brush-type jar washing machine for container cleaning

Industrial Steam Autoclave for Sterilization

Conveyor system (Wide Conveyor (Transporter) with Plate Chain)

Metal Floor Tile for Industrial Use