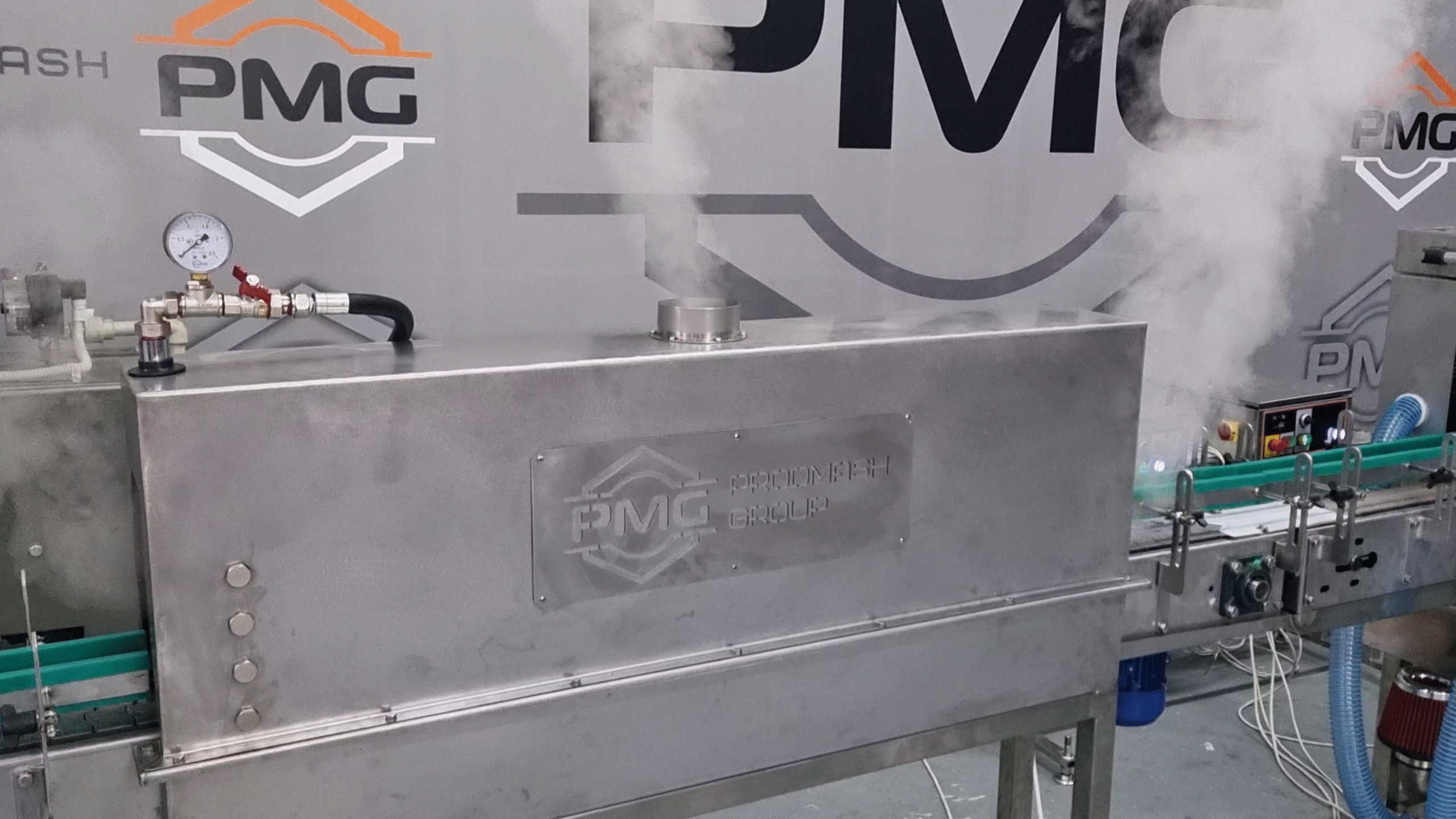

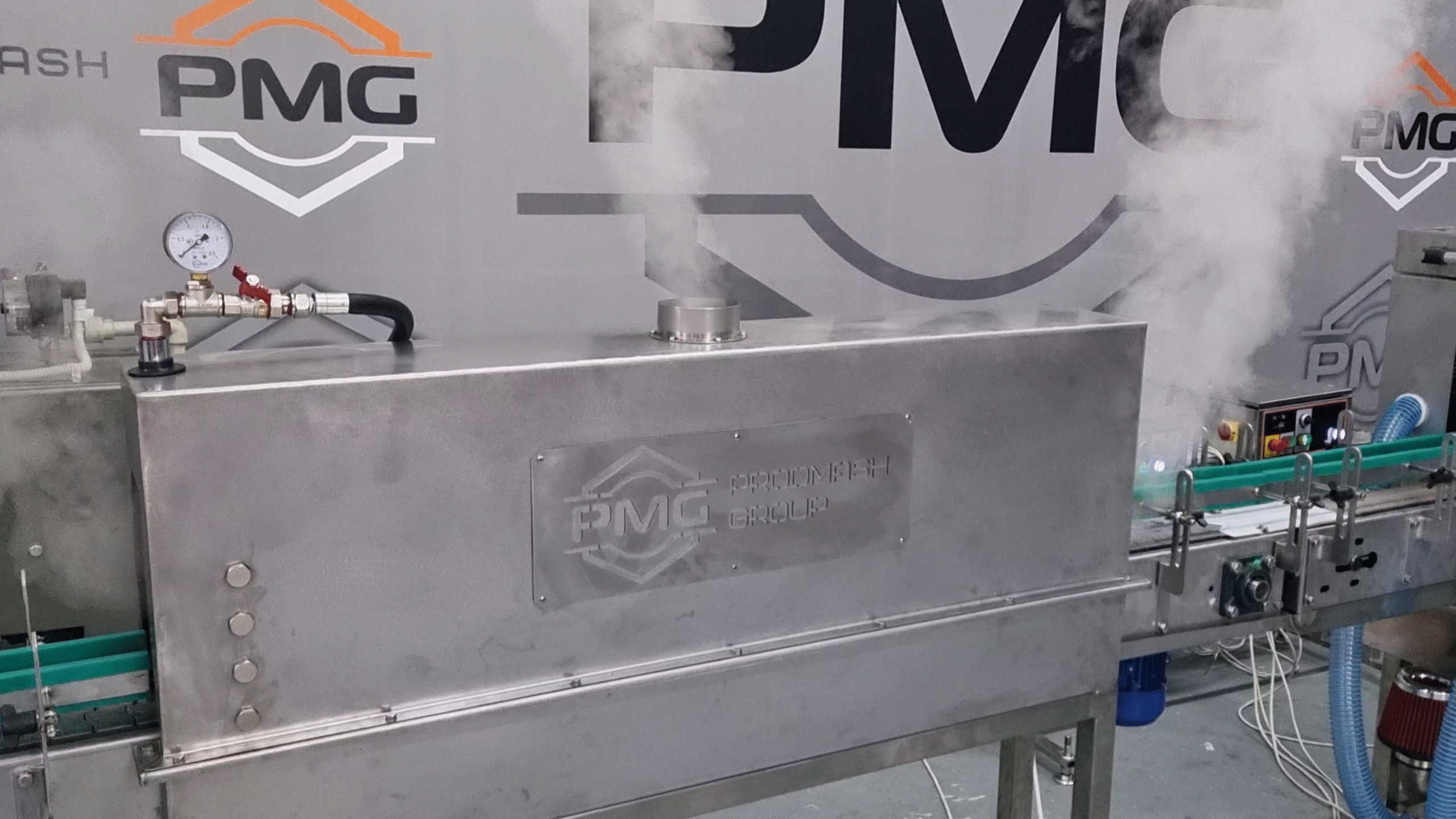

Heat-shrink tunnel machine (steam tunnel)

The steam shrink tunnel is designed for heat-shrinking labels on plastic, glass, and metal containers. The even steam distribution ensures precise label fitting without deformation. A reliable solution for food, beverage, chemical, and canning industries

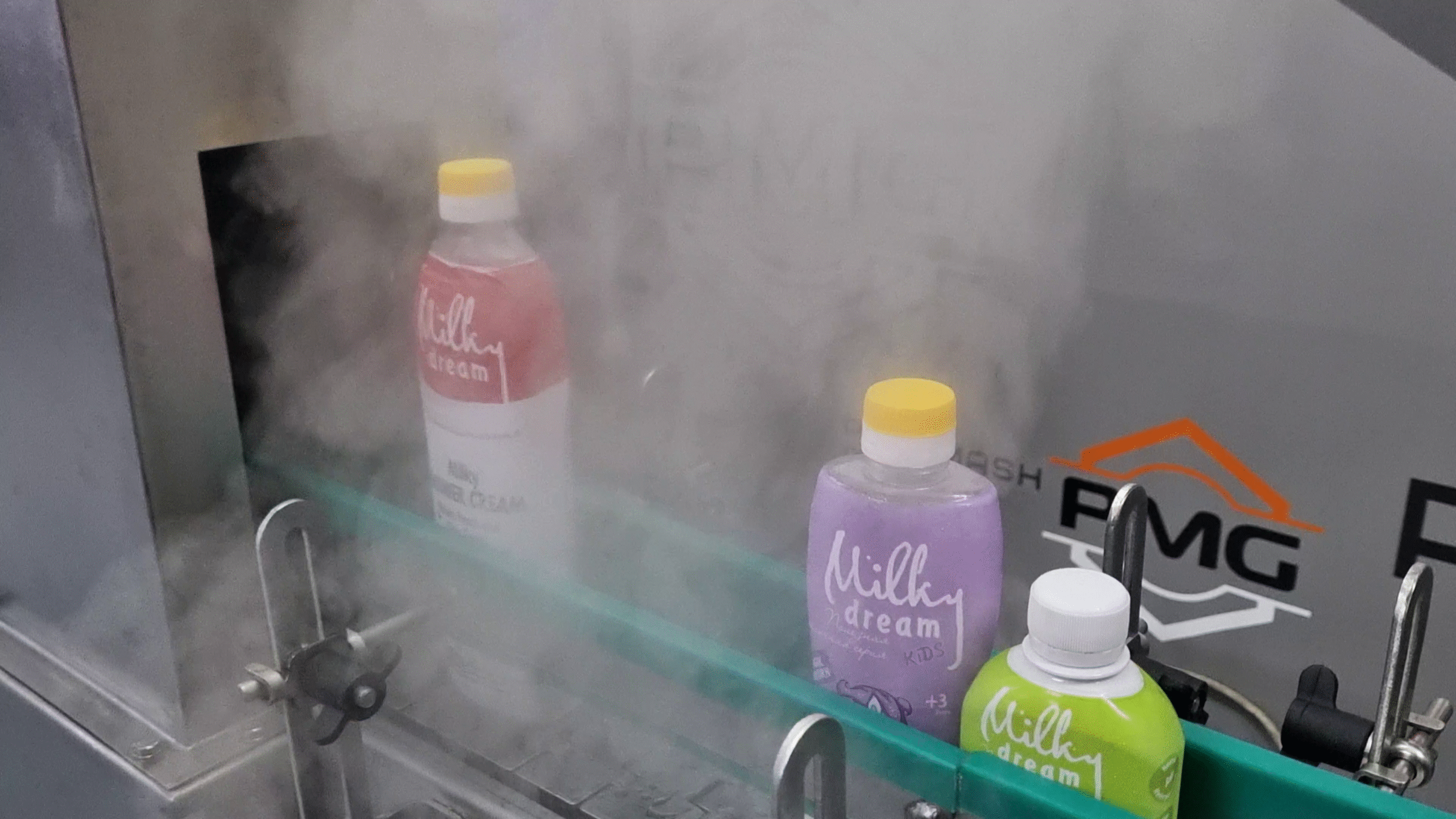

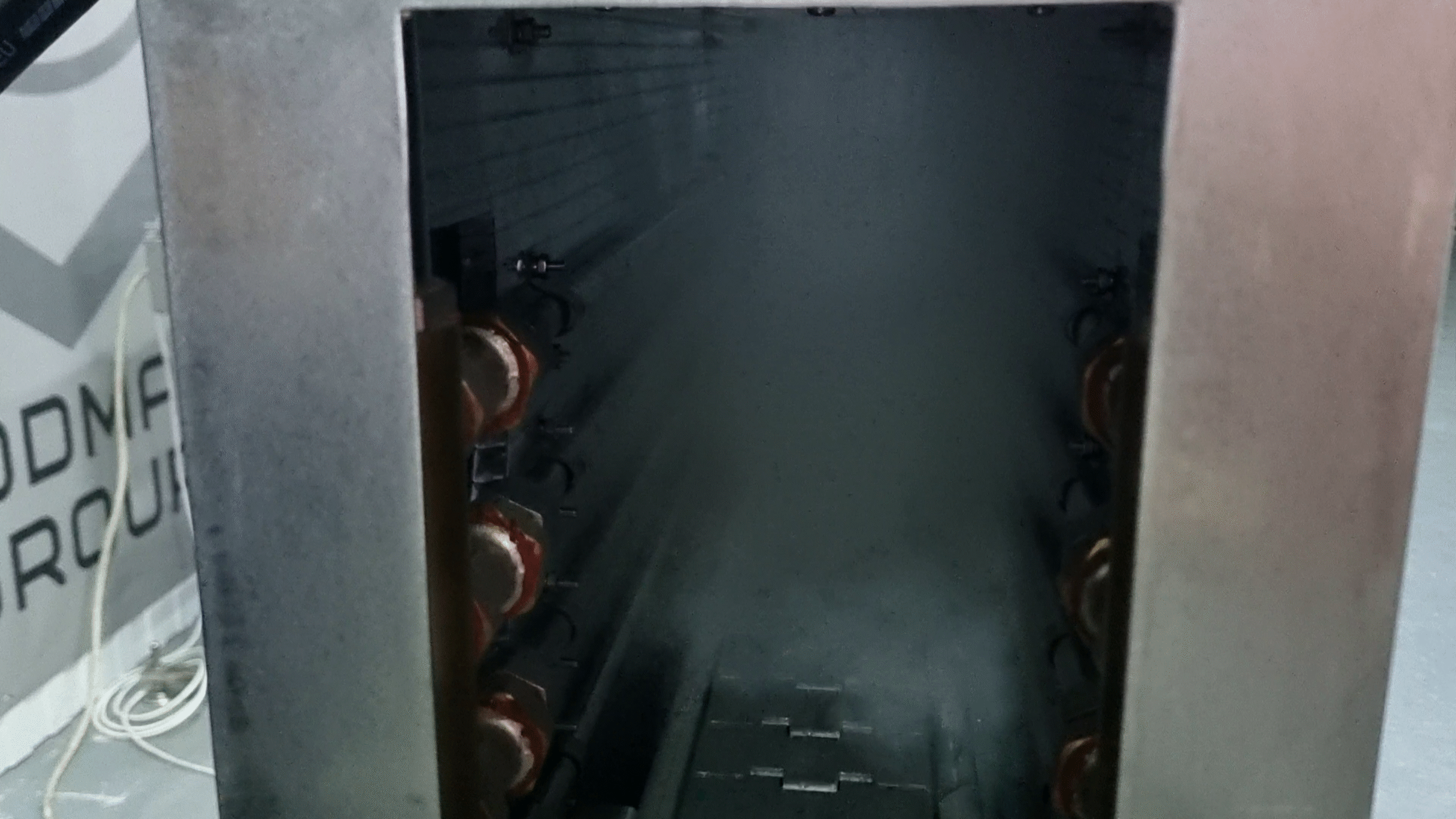

The steam shrink tunnel is used for shrinking film labels (PVC, PET, OPS) on containers of various shapes and sizes. Steam evenly distributed inside the tunnel ensures smooth and tight label adhesion to the container surface.

The equipment integrates easily with automatic labeling lines and steam generators. Temperature and steam supply are adjustable to meet specific material and label thickness requirements.

The tunnel’s body is made of stainless steel, providing durability, moisture resistance, and easy maintenance. It’s suitable for use in labeling and packaging lines for canned foods, beverages, cosmetics, and household chemicals.

Advantages:

-

even shrinkage over the entire container surface;

-

adjustable temperature and steam flow;

-

supports containers of various shapes and sizes;

-

reduced energy consumption through steam heating;

-

stainless steel construction;

-

high processing speed and stable operation.

Applications:

-

canning industry — shrink labeling of jars and cans;

-

food and beverage production — sauces, juices, drinks;

-

chemical and cosmetic industries — shrink labels on bottles and flasks.

Technical specifications

| Machine type | linear, continuous operation | |

| Technical productivity: | pcs/hour | 6,000 |

| Total installed power, no more than | kW | 0.3 |

| Machine dimensions

length width height |

mm |

2500 ±50 500 ±50 1500 ±50 |

| Area occupied, no more than | m2 | 1.25 |

| Machine weight with one set of replacement parts | kg | 90±20 |

| Three-phase current network with grounded neutral

voltage frequency |

V Hz |

230± 10 50± 1 |

Інші наші товари

MANUAL sealing machine 2

MANUAL sealing machine 1

Semi-automatic sealing machine

AUTOMATIC sealing machine

AUTOMATIC Lux sealing machine

Slat Chain Conveyor for Containers

P1-BWM Brush-type jar washing machine for container cleaning

Industrial Steam Autoclave for Sterilization

Conveyor system (Wide Conveyor (Transporter) with Plate Chain)

Metal Floor Tile for Industrial Use