Industrial Steam Autoclave for Sterilization

The industrial autoclave is designed for sterilizing and heat-treating food products in jars, bottles, and other hermetically sealed containers. It operates with high-temperature steam, ensuring complete destruction of microorganisms without compromising product quality. Used in canning, meat, fish, and baby food production. Automated temperature and pressure control ensures stable and safe operation. Made of stainless steel for long service life.

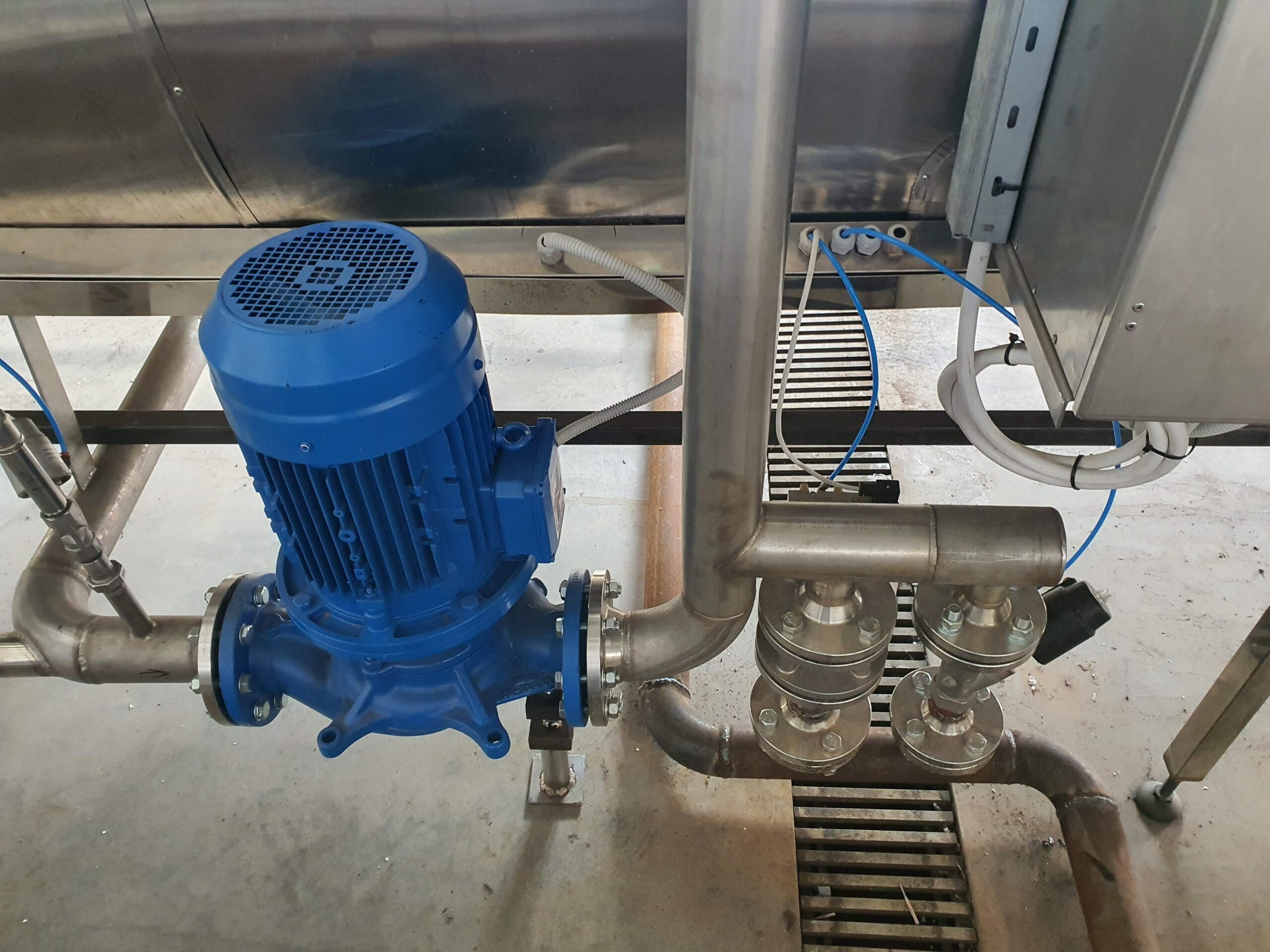

The industrial steam autoclave is a high-efficiency unit for sterilizing and thermal processing of canned products in sealed containers (jars, bottles, or trays). The process is carried out with high-temperature steam or a water-steam mixture, ensuring uniform sterilization throughout the batch.

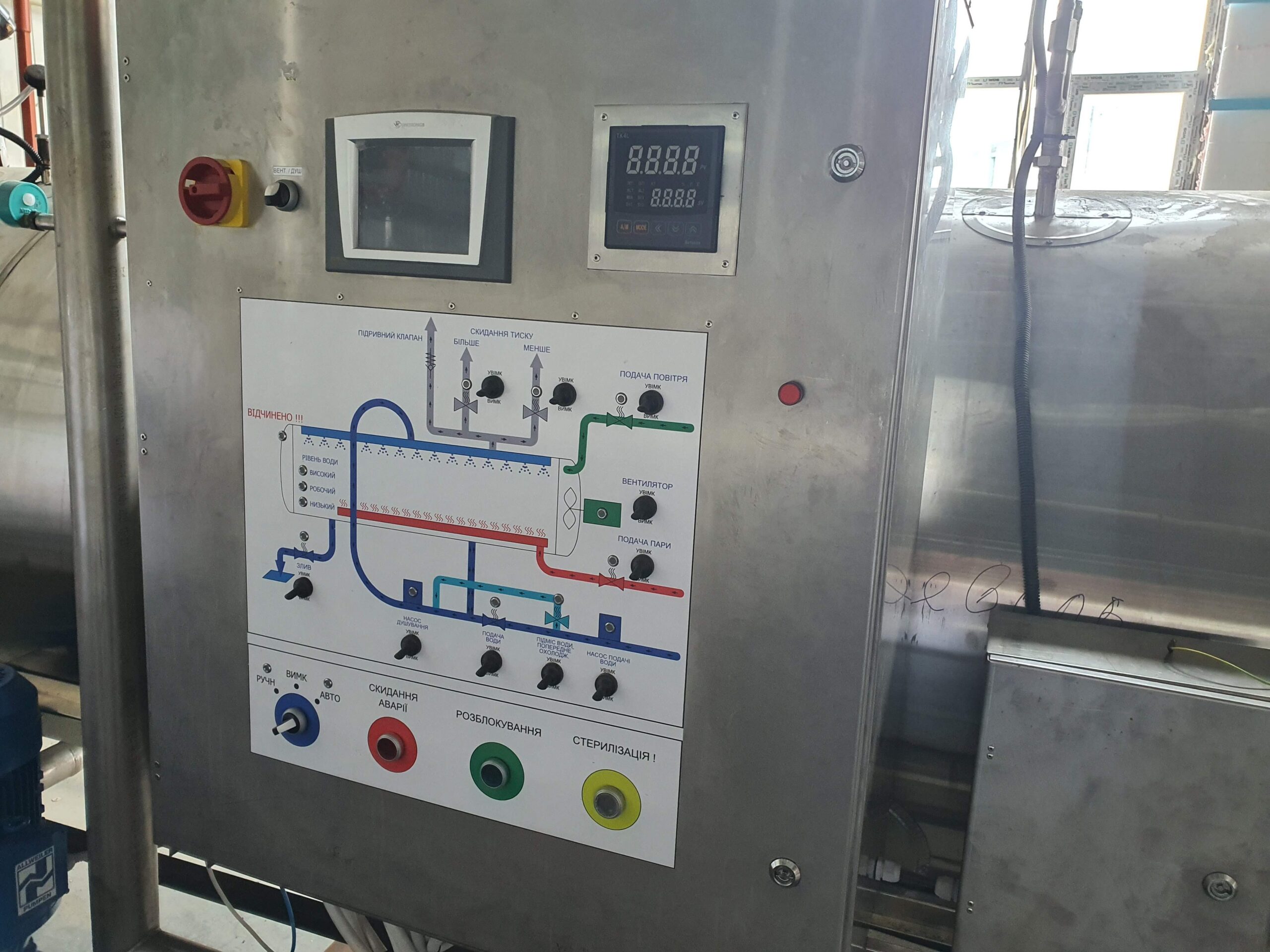

Autoclaves are equipped with automatic temperature, pressure, and cycle control systems, allowing precise adjustment for various types of products — vegetable, meat, fish, or fruit preserves. Gentle sterilization modes help retain the natural structure, color, taste, and nutritional value of foods.

The construction is made of AISI 304 or AISI 316 stainless steel, ensuring durability, corrosion resistance, and compliance with sanitary standards of the food industry. The autoclave can be equipped with automatic loading/unloading systems, programmable processing cycles, and a multi-level safety control system.

Advantages:

-

Uniform sterilization of the entire batch;

-

Preservation of taste and nutritional properties;

-

Fully automated process control;

-

High energy efficiency and minimal heat loss;

-

Stainless steel body resistant to moisture and chemicals;

-

Easy maintenance and long lifespan;

-

Integration capability with production lines.

Applications:

-

Canning industry — sterilization of vegetable, fruit, meat, and fish products;

-

Baby food production — gentle thermal processing;

-

Food industry — heat treatment of sauces, pâtés, and beverages.

The industrial autoclave is a key component for production facilities seeking reliable, safe, and high-quality sterilization to extend product shelf life while maintaining nutritional value.

Technical specifications

| Machine purpose | Sterilization, cooking, and autoclaving | |

| Number of baskets | pcs | From 1 to 5 |

| Total installed power, no more than | kW | 15 |

| Machine dimensions (5 baskets)

Length Width Height |

mm |

5850 ±50 1600 ±50 2450 ±50 |

| Basket dimensions | mm | 800*800*750 |

| Machine weight | kg | 2500 |

| Three-phase current network with grounded neutral

voltage frequency |

V Hz |

380± 38 50± 1 |

Інші наші товари

MANUAL sealing machine 2

MANUAL sealing machine 1

Semi-automatic sealing machine

AUTOMATIC sealing machine

AUTOMATIC Lux sealing machine

Slat Chain Conveyor for Containers

P1-BWM Brush-type jar washing machine for container cleaning

Conveyor system (Wide Conveyor (Transporter) with Plate Chain)

Metal Floor Tile for Industrial Use

Jar and Container Drying Machine (Tunnel Industrial Dryer) MS-1.0